rotary drum dryer

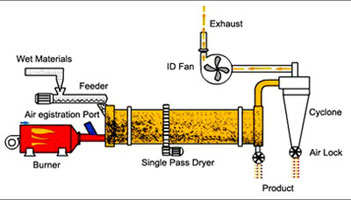

In single pass dryer, wet materials is mixed directly with hot air inside the rotating insulated drum. The wet materials and hot air normally flow concurrently through the dryer so the hottest gases come in contact with the wettest material. The exhaust gases leaving the dryer may pass through a cyclone, multi-cyclone, baghouse filter, scrubber, ESP or WESP to remove any fine material entrained in the air. An ID fan is usually placed after the emissions control equipment to reduce erosion of the fan, but may also be placed before the first cyclone to provide the pressure drop through downstream equipment.PROCESS FLOWCHART OF ROTARY DRYER

ADVANTADGE OF DRYER SYSTEM

- High quality of dry product

- High energy efficiency of the process

- Flexible and simple operation

- Low operating and maintenance costs

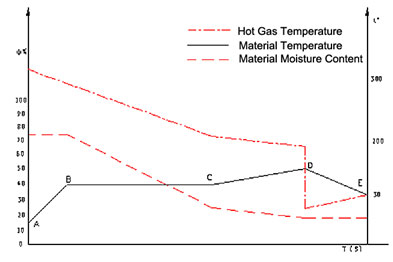

ANALYSIS OF DRYING CHARACTERISTIC

According to the characteristic of biomass product, there are four period of drying(Cooling Period will be determined based on the process requirement)

BC:Constant Rate Period

CD:Falling Rate Period

DE:Cooling Period

Project pictures

Hot gases are contacted with wet material inside a rotating drum. The rotation of the drum, with the aid of flights, lifts the solids in the dryer so they tumble through the hot gas, promoting better heat and mass transfer. Hot flue gas can be fed directly into the dryer. Other options include using a burner or a steam heater to raise the temperature of incoming air. Single pass dryer can accept a fairly wide range of particles sizes, moisture content or throughput and still achieve high drying rates. The design permits the use of the highest possible drying temperatures.